L3Cert

Title: Level 3 Certification “The Big One”

Location: H³ Workshop 1

Date: Jan 21, 2015 – Mar 13, 2016

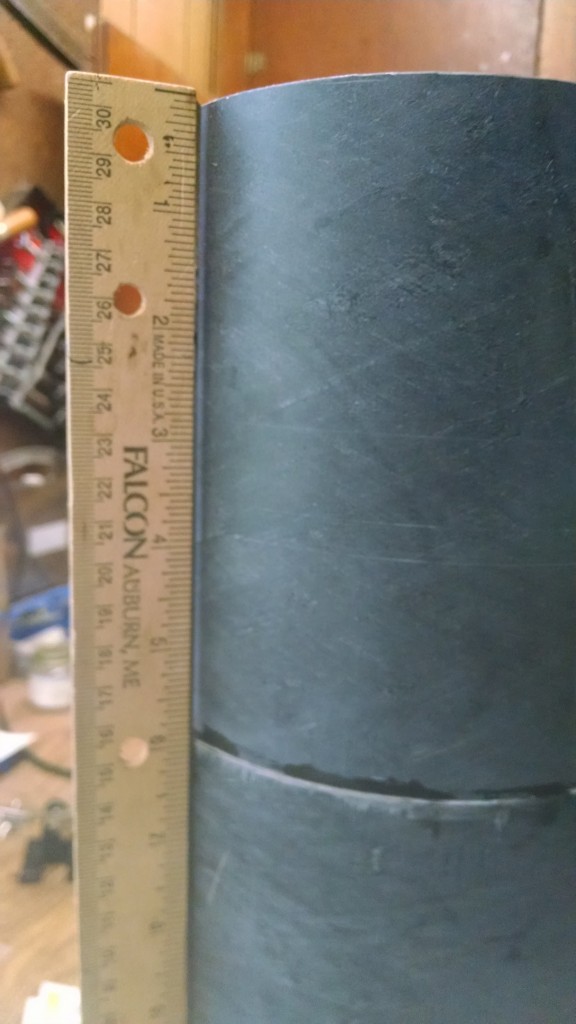

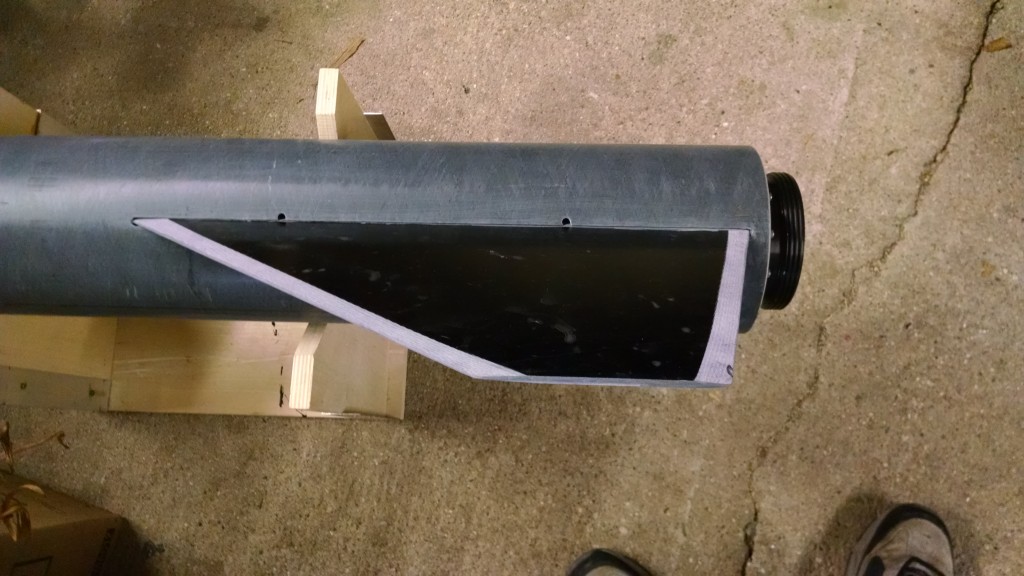

Description: Ultimate Wildman Kit – 6in x 10.5ft fiberglass kit

Builder: Russell Hall

Project Mission Codename: H³RL3 (Rocket Level 3)

Total weight with M1830 is 49.1lb

![]() Hall L3 Construction Package D1.8 Updated Feb 23,2016

Hall L3 Construction Package D1.8 Updated Feb 23,2016

Jan 21, 2015 UPS Delivery

M1830, L990 and my daddy’s VMAX

Bath Time

Got my sanding face on… March 22 2105 30* out side

Got my sanding face on… March 22 2105 30* out side

Cleaning up a centering ring

Cleaning up a centering ring

sanding the root of a fin

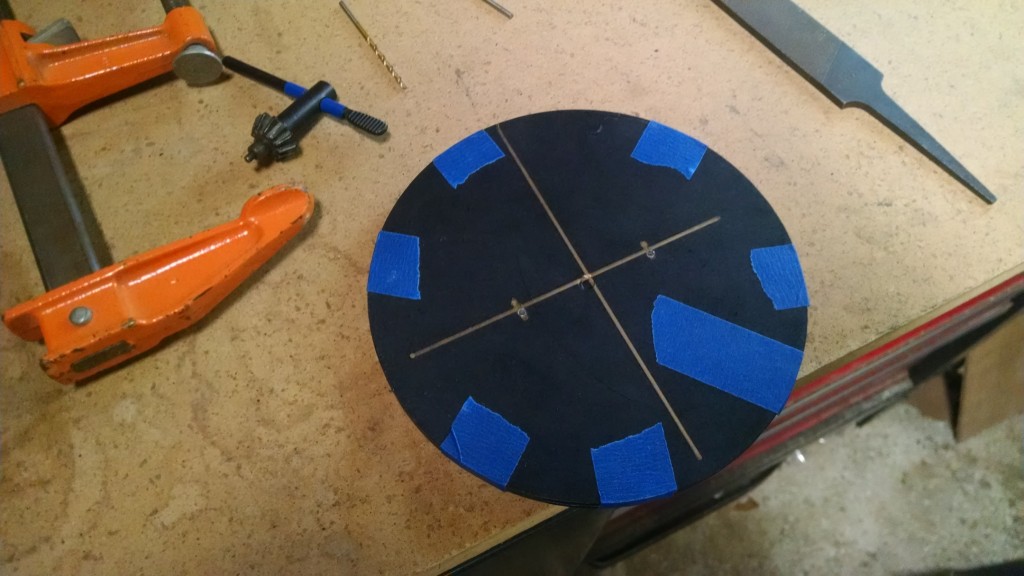

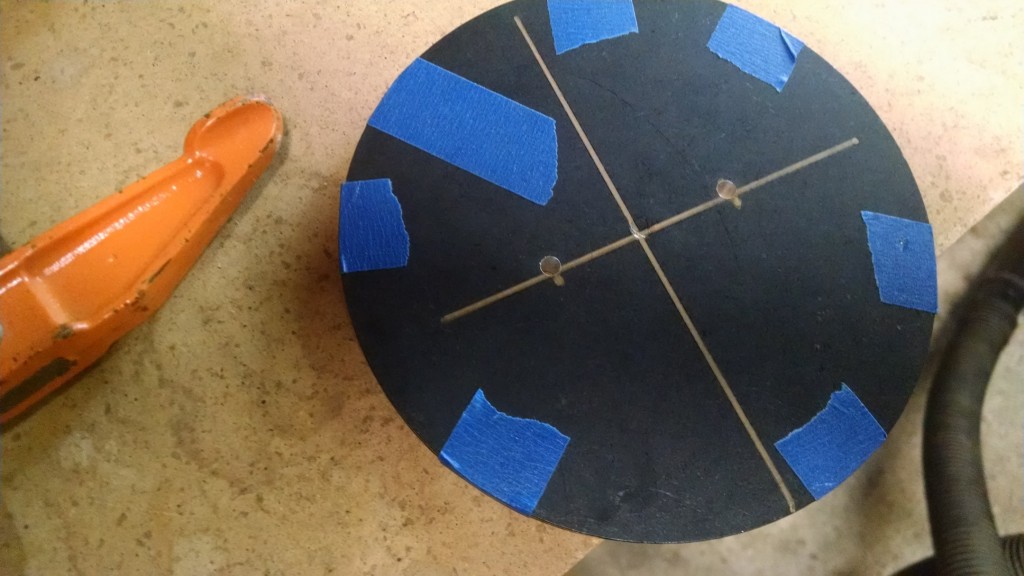

Marking centering rings with 1 inch spacing 180* apart March 29, 2015

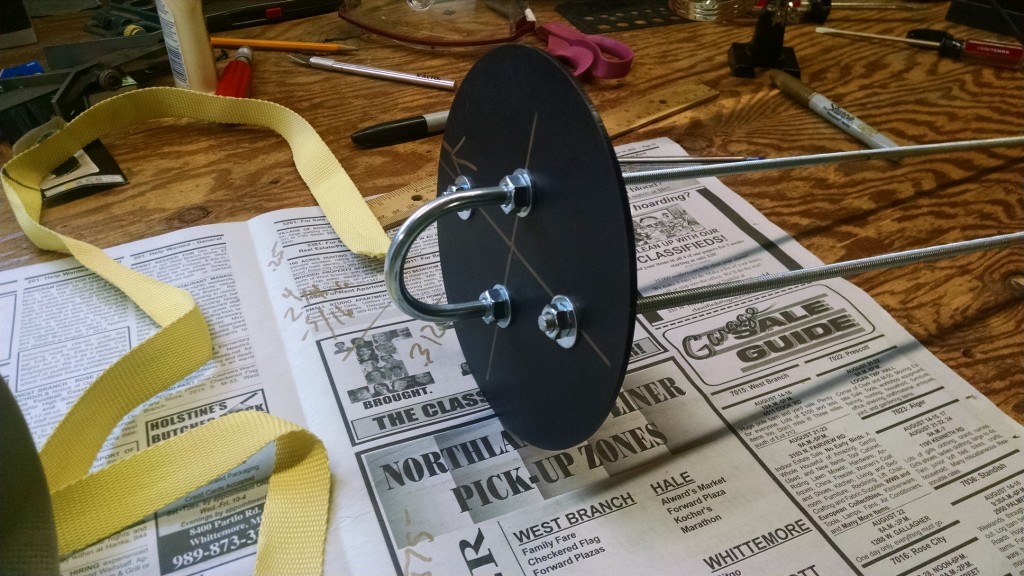

Two centering rings notched out for kelver bridle

CA tacked the front two centering rings

Rock-Poxey the ‘top’ of the centering rings on the motor tube

epoxy added to the bottom of the centering ring

First layer of Rock-Poxey down before the strap goes down.

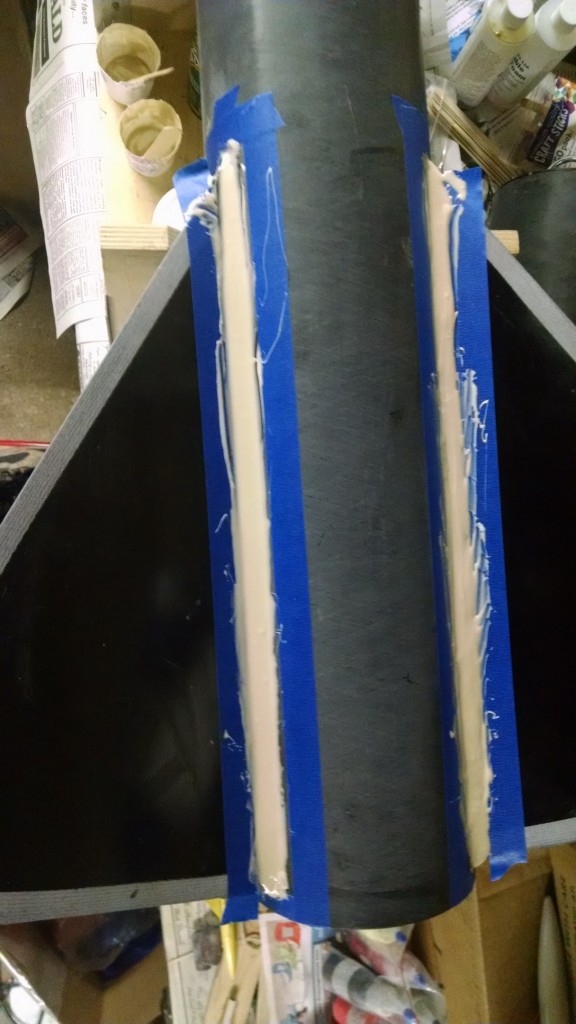

blue tap is to keep the epoxy out of the B Fin root mount

blue tap is to keep the epoxy out of the B Fin root mount

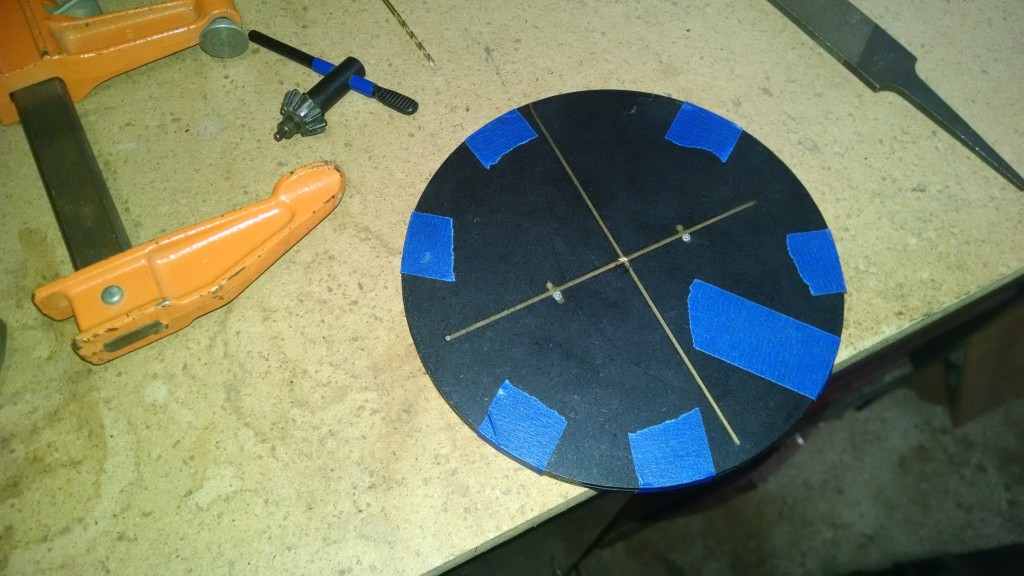

Making the base centering ring to mount the motor retainer to.. it’s too big 😉 April 8, 2015

the centering ring needs a 4in hole in it

the centering ring needs a 4in hole in it

I used my dad’s 4in nose cone to line up the retainer to the centering ring

I used my dad’s 4in nose cone to line up the retainer to the centering ring

First couple of taps for the retainer

First couple of taps for the retainer

all of the taps are in, and it fits

all of the taps are in, and it fits

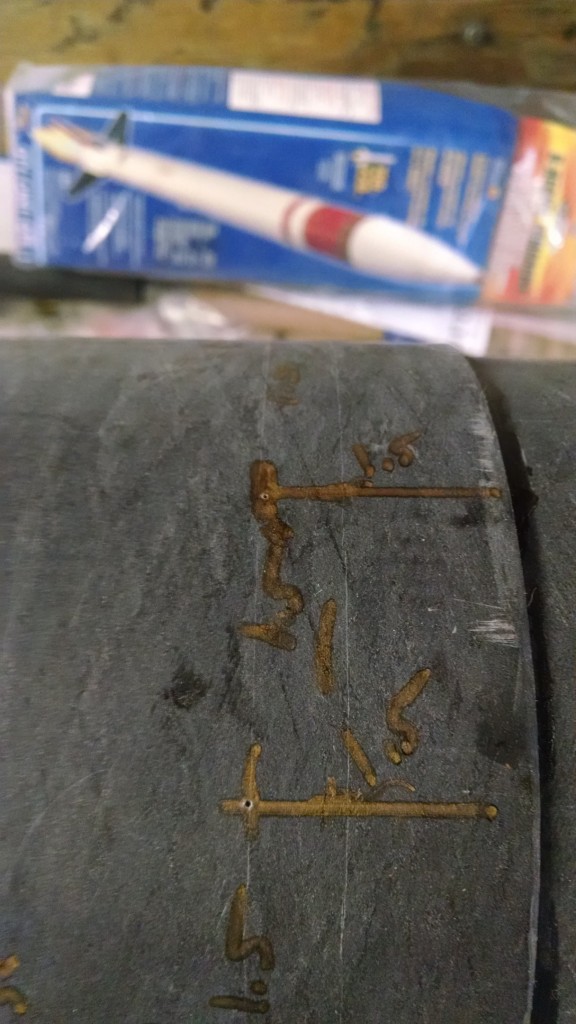

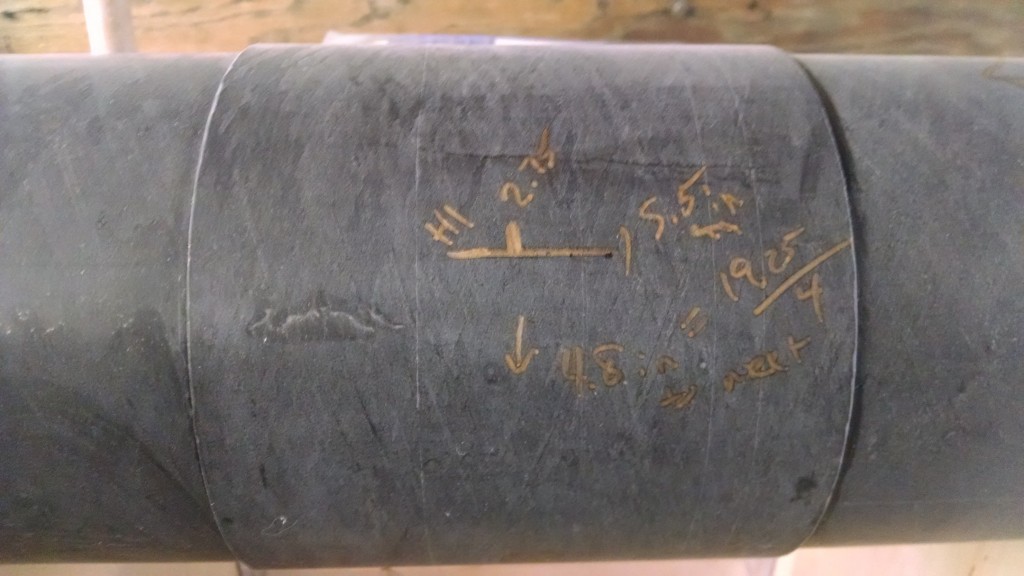

Marks made on the booster tube. Rail guild well mounts 3/8in holes one at 2 inches from bottom and the other at 25in from bottom. Center of pressure is at 30inches from bottom.

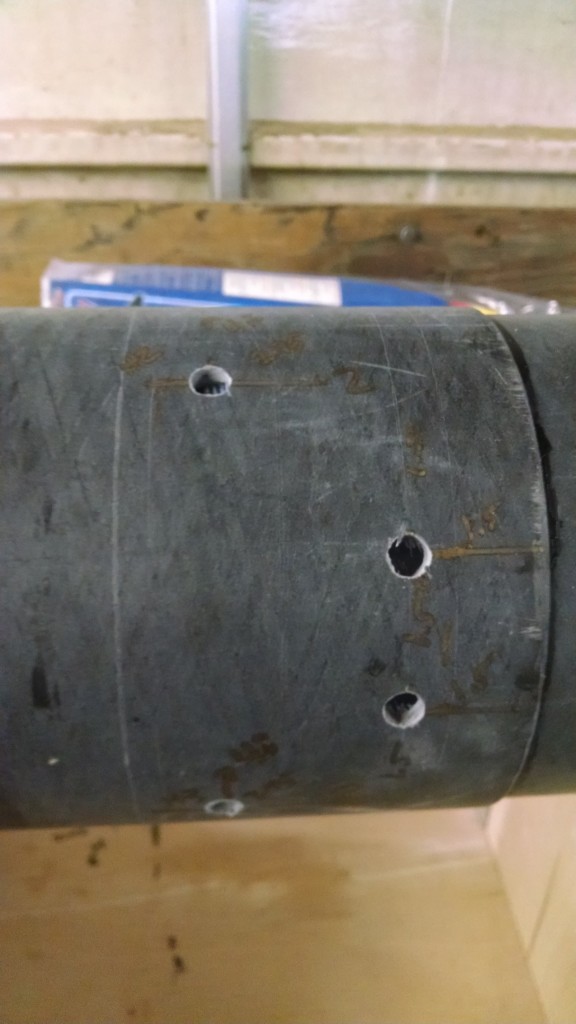

5/32in hole drilled 15inches from top of booster for a pressure vent hole. April 12, 2015

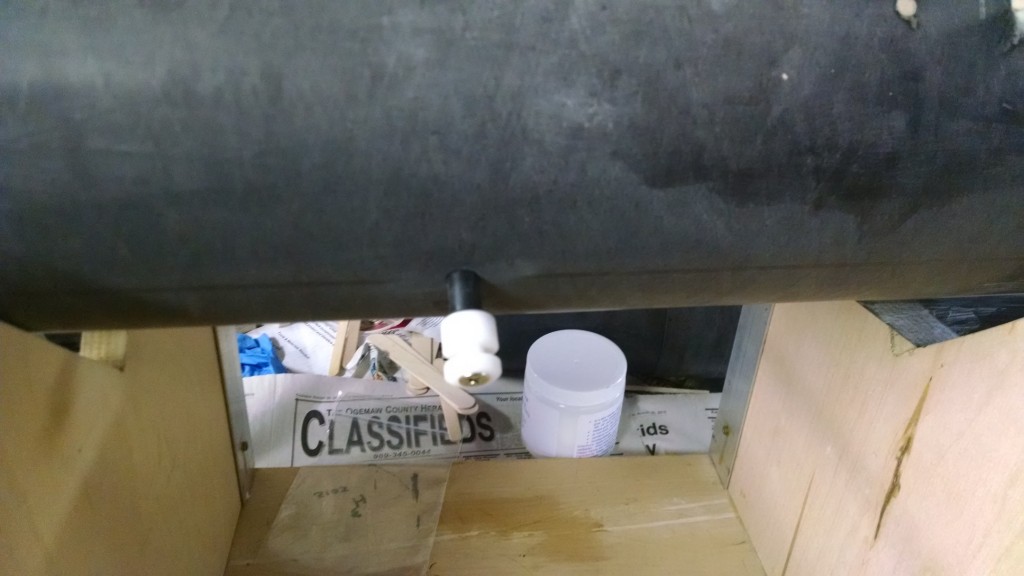

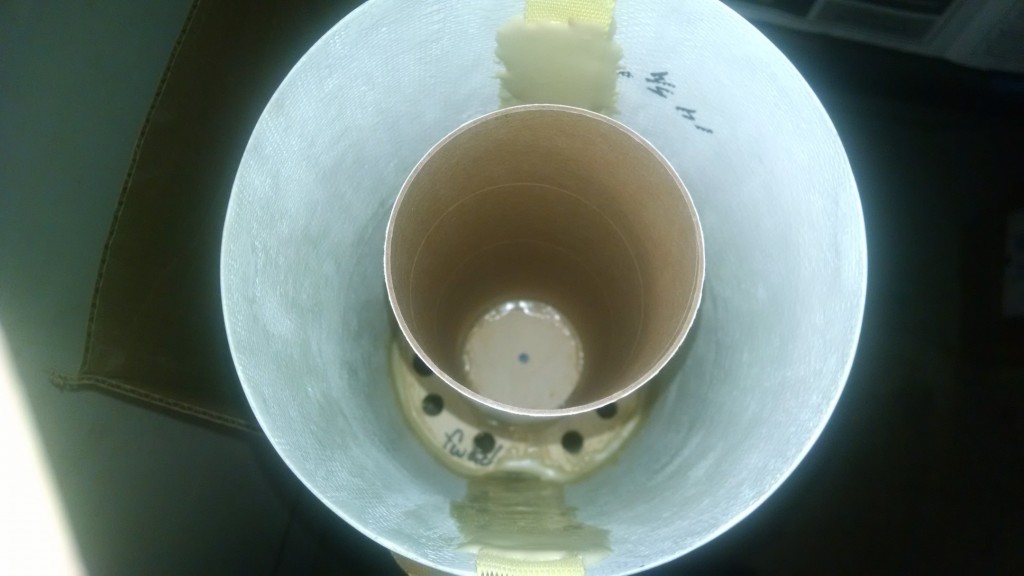

Motor tube dry fit in booster tube without epoxy on the rear wood centering ring

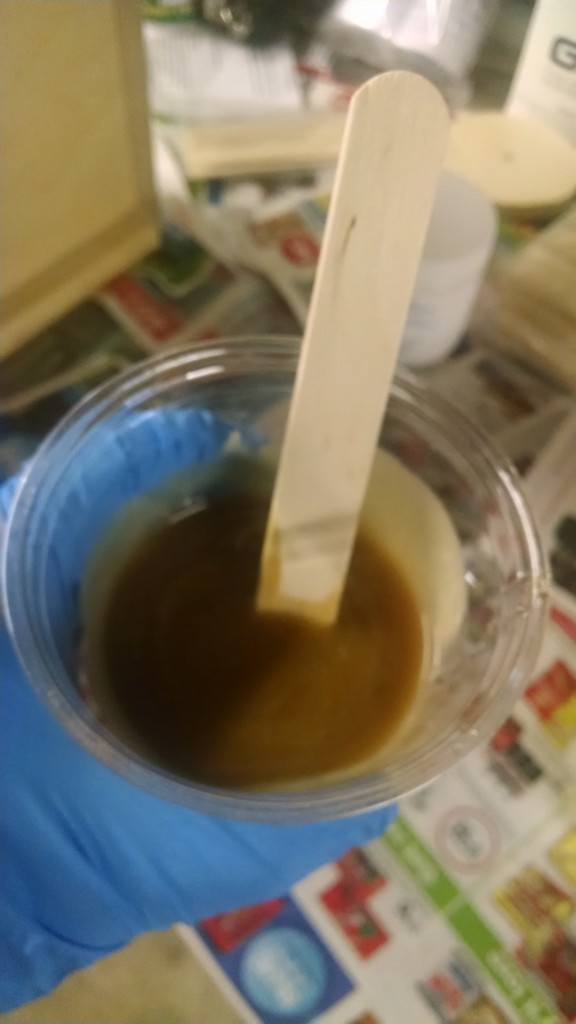

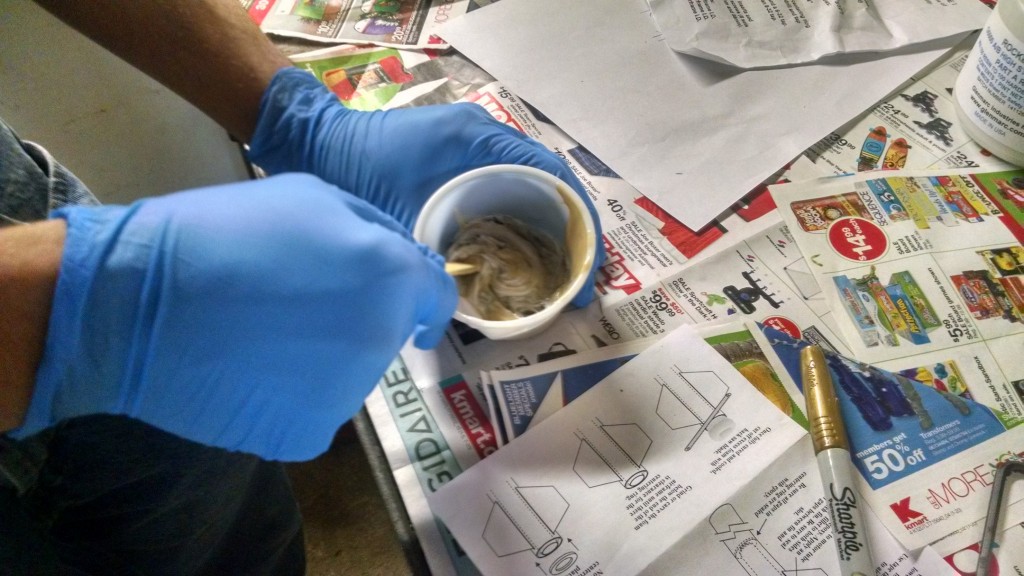

Rock Poxey with chipped carbon fibers for internal fillets April 21, 2015

adding 30ml of rockpoxey mix to internal fillet between forward centering rings

Getting the first fin tacked on. I use the double peanut butter way of putting the rock-poxy down. So you put a good lay on the root of the fin, put it into the rocket then pull it out, re-apply then re-insert it into the rocket. When it’s in then I use an alignment tool to get it in the right spot. May 18, 2015

fin #2 buttered up May 19, 2015

Sammie supervising the project. May 19, 2015

Fin #3 tacked down and aligned up May 20, 2105

Adding internal fillets to the bottom of the centering ring. 12ml per hole.. should give me 24ml between each fin set. May 24, 2015.

Inserted 15ml of epoxy mix with chipped carbon fiber on each side June 5 2015

Sanding the inside on the nose cone June 5 2015

Mix up the rockpoxy with black die for the ebay

Making a mess with the ebay

Getting the switch band into the right spot.. and making a mess

Rubbing alcohol and paper towel is great for cleaning a mess…

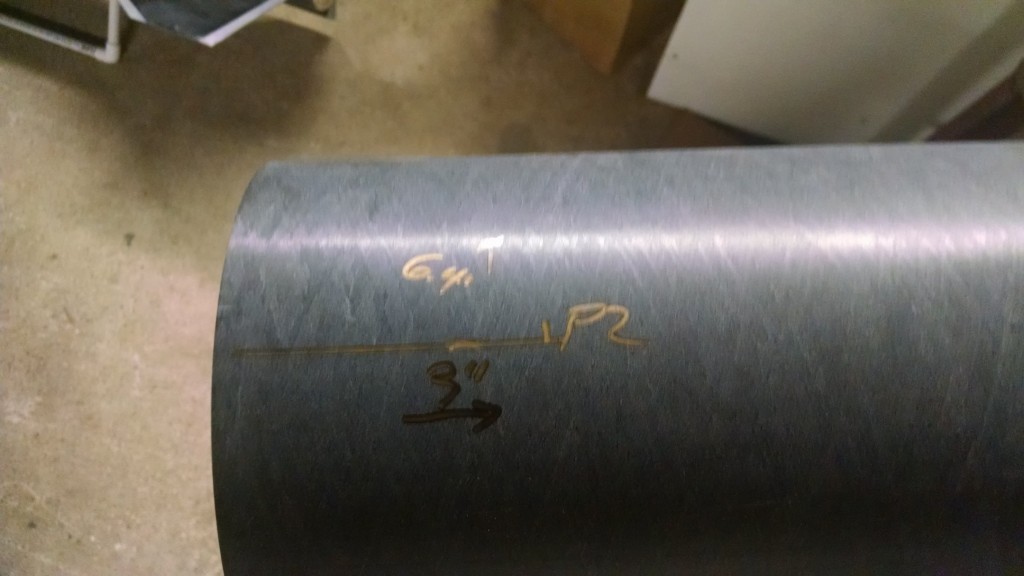

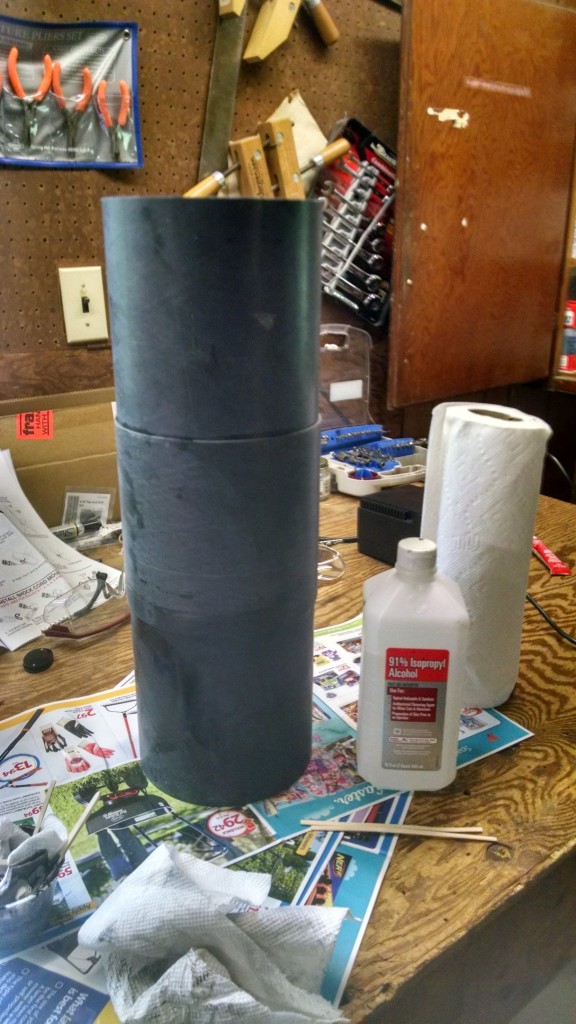

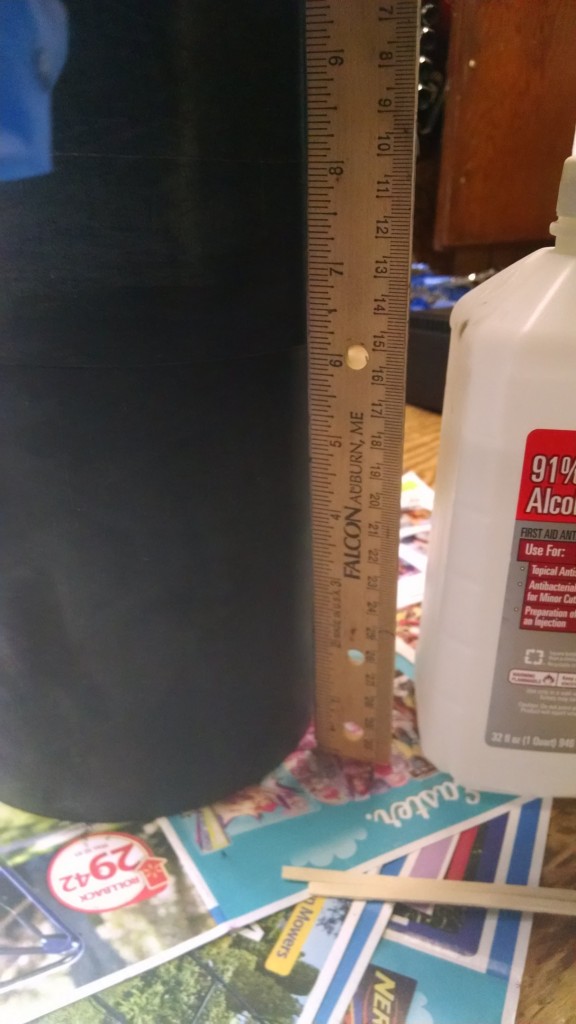

6 inches both ways.. with a 6 inch switch band. makes 18 inches

just messing around to see what a short stack looks like June 7 2015

put the rear rail guide June 17 2105

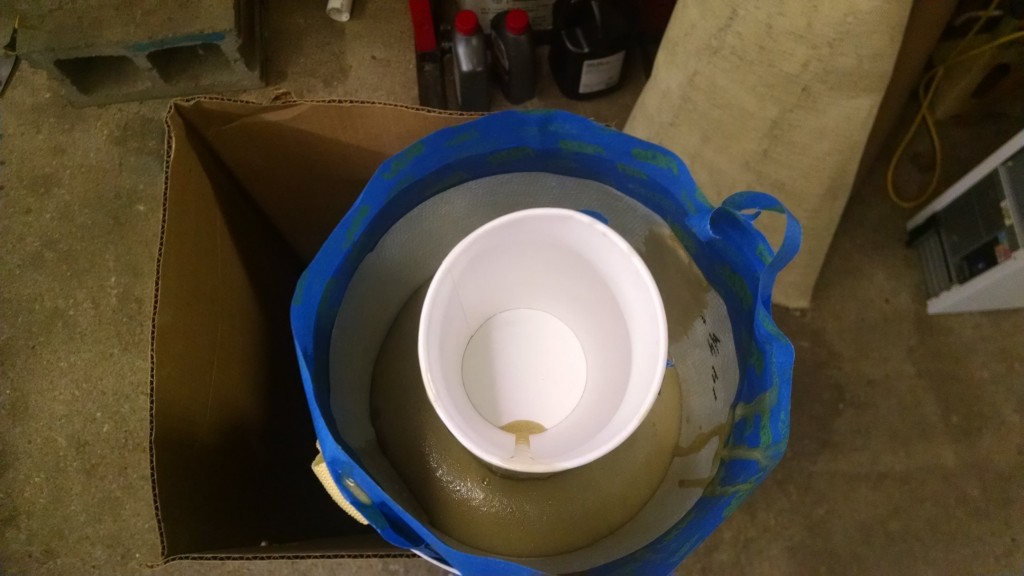

getting my foam on.. 4oz of each was need in each fin space for a total of 8oz

mix the foam up.. Needed more tape 🙁

Needed more tape 🙁

Clean up time.. Acetone to loose up the foam that came out. August 16, 2105

It cleaned up well with some sanding

An other side

Taped up the holes with the tapes for the retainer, to keep the epoxy out, August 18 2015

rear end of the fin can before rear centering ring with retainer screws was installed.. lots of foam.

rear centering ring epoxied in.

Fillet around the rear center ring on the outside.. I will need to sand down the motor tube to match the ring. August 22, 2105

Measured out 14.5 inches of 1 inch kelver bridle

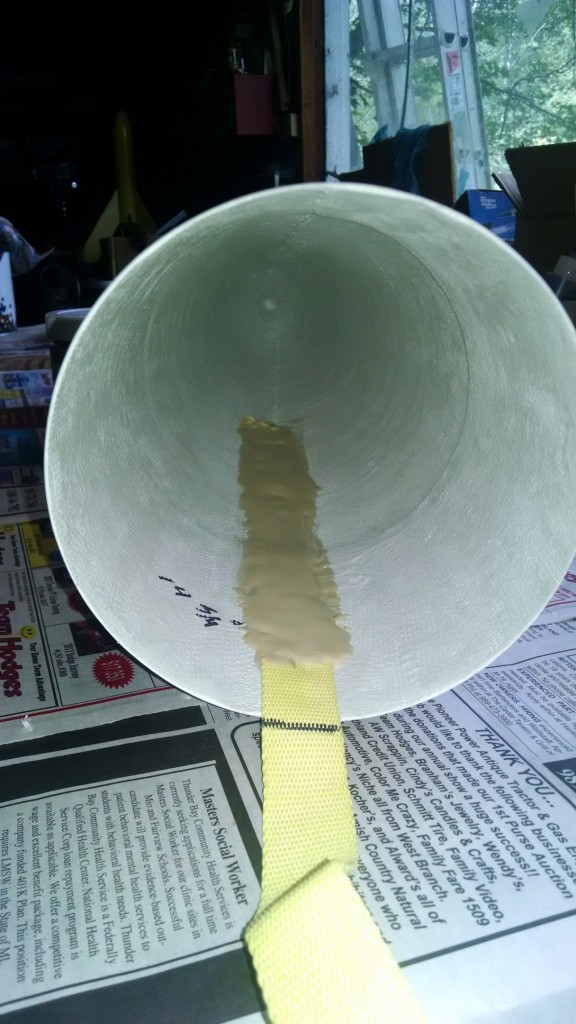

kelver bridle epoxied down on the seam of the fiberglass nose cone

Time to work on the ebay bulkheads.. these are punched for the 5/16 ubolt

pilot hole drilled

Finished holes with hardware installed

back side of both.. they need some epoxy on the nuts to protect them and keep them from coming off.

comparing the 3in ebay to the 6in ebay 🙂 I like it!

Second kelver bridle epoxied in. August 23, 2015

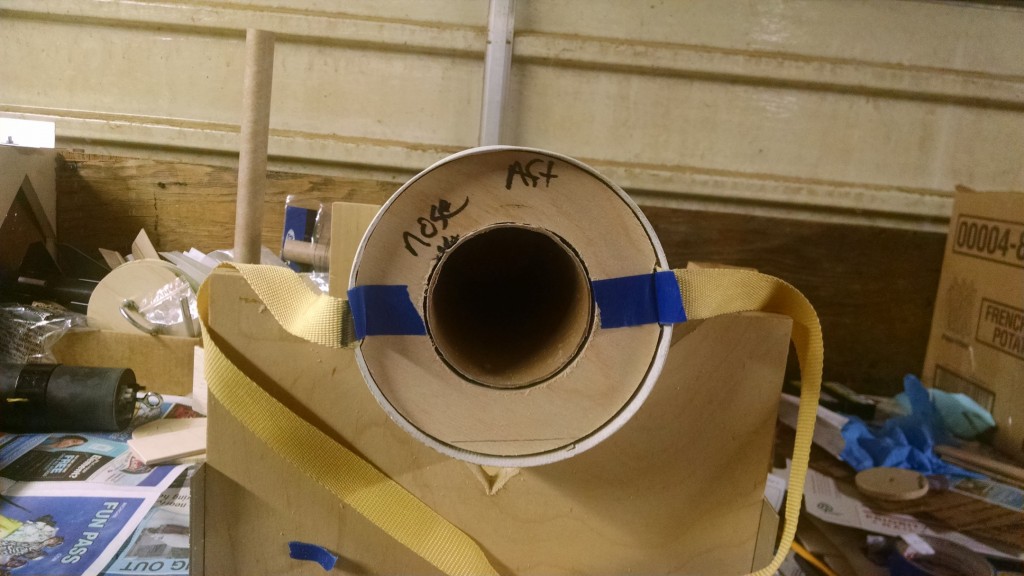

Moded the nose cone rings so they will fix in with the strips in the nose cone.. next to the tube that is going in for a tracking bay. August 27, 2015

holes added to the forward centering nose cone ring for the 2part foam to get to the top of the nose cone.

nose cone ring epoxied in and installed.

prepping the first set of external fillets.. making a mess!

I used a 38mm motor tube to make the fillets look pretty!!

And looking good!!

Sammie inspecting the second side of external fillets September 5 2015

She got distracted with the cats out side…

I like it.. second side from the back.

Third and final fin fillet Sep 9, 2015

I need to sand down the motor tube, just a little bit so the motor retainer can sit flush. Sep 12, 2015

it’s a dirty job, but someone has got to do it.

Lets get more work done on the nose cone, drop some expanding foam in the tip of the cone. Sep 22, 2105

Insert 3in tube for tracking bay in the nose cone, epoxied the tube in place.

Add some more foam and watch it grow . Sep 23, 2015

So, the holidays are here… now we take some time off…

I added some tape around the edge, less mess this way.. Jan 20, 2016

All full now, time to let it set and then start hacking out the extra. Jan 23, 2016

and screw it in, this will pull the nut and the rubber down and that will secure it down.

Mark up the ebay for the static ports, need 4 x 0.5in holes 4.8in in separation

Add the switch ports as well.. it is 1.5in from the aft side and 1.5 in form each static port.

A little help getting the drill bit started

A little bigger

Look at that.. 0.5 inch holes

A little sanding to clean up the drill holes

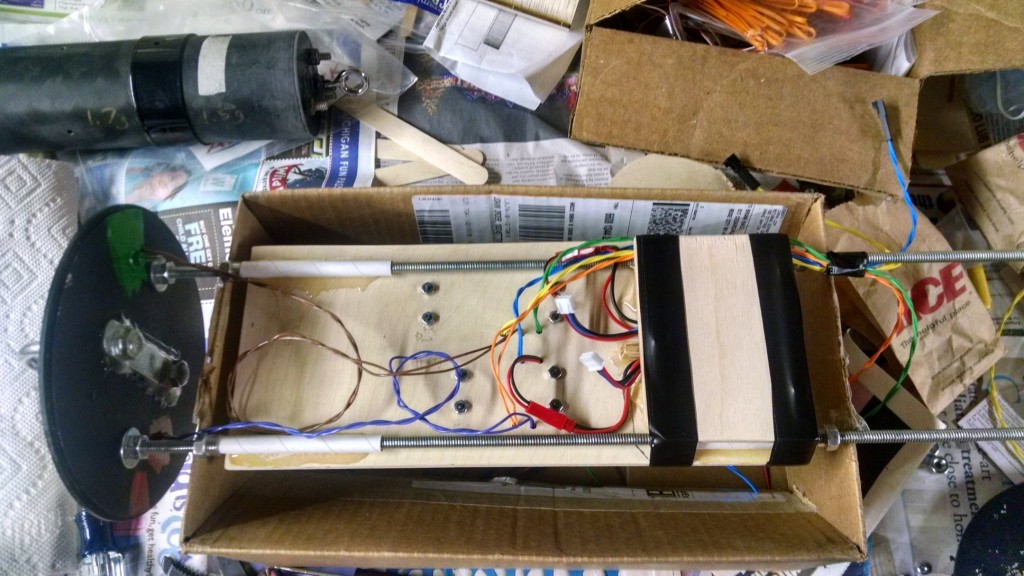

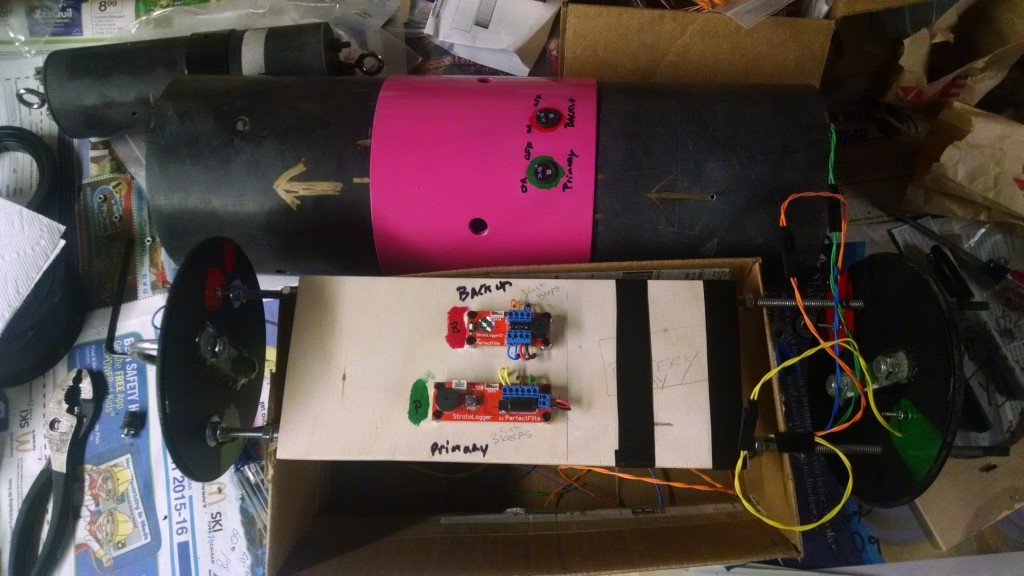

Got the ebay and the payload bay lined up

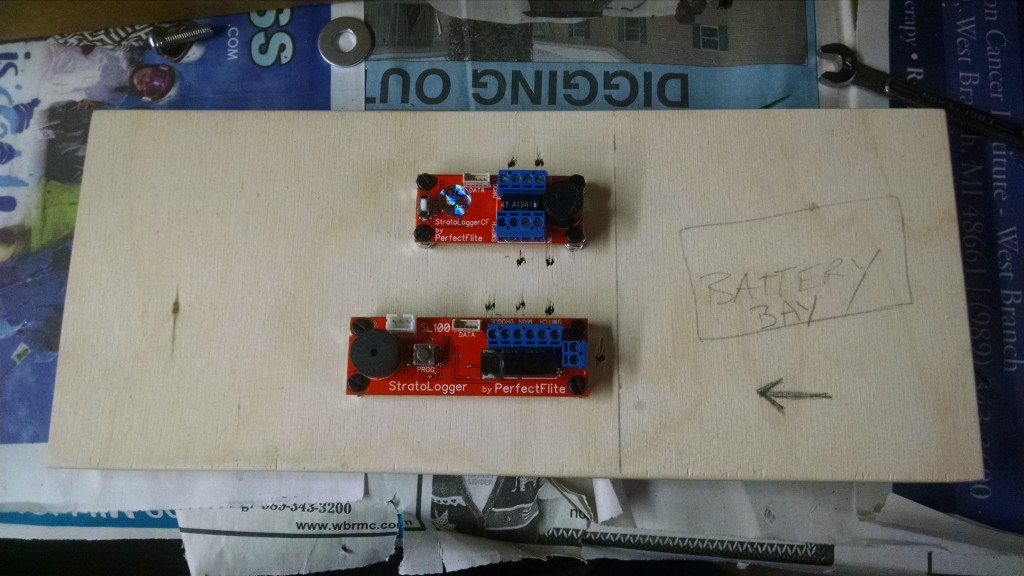

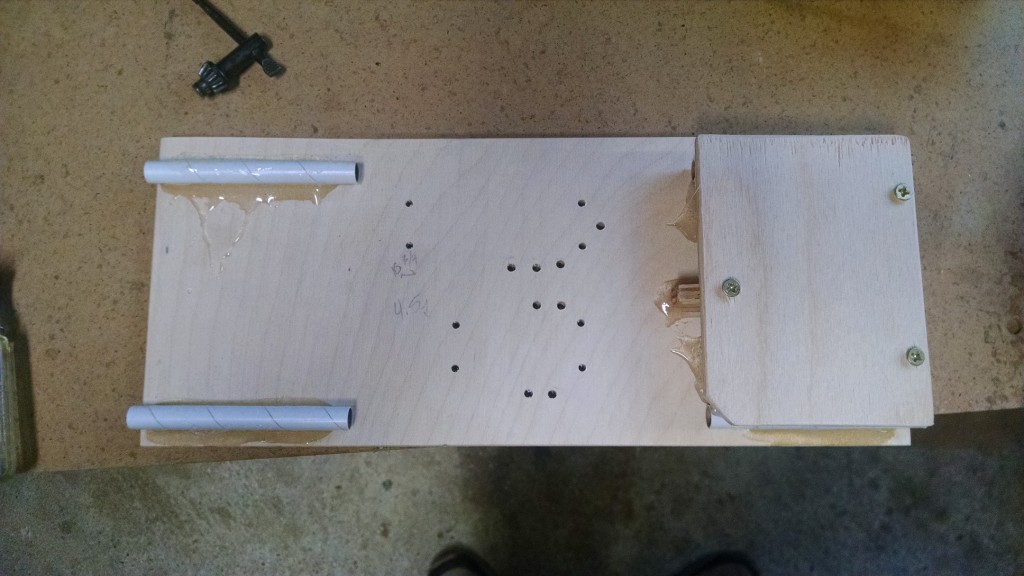

Got the ebay sled cut out 4.5in x 10.75in with some 1/4 in lugs lined up

With a little 5min west system epoxy, the sled and lugs are secured down.

I forgot to add the holes for the deployment charge wires.. problem fixed Jan 26, 2016

The u-blots are too long.. so they need to be shorter

Both side by side, with trimmed down u-blots

I added some 5-min epoxy to cover up the sharp edges, and to keep the nuts on.

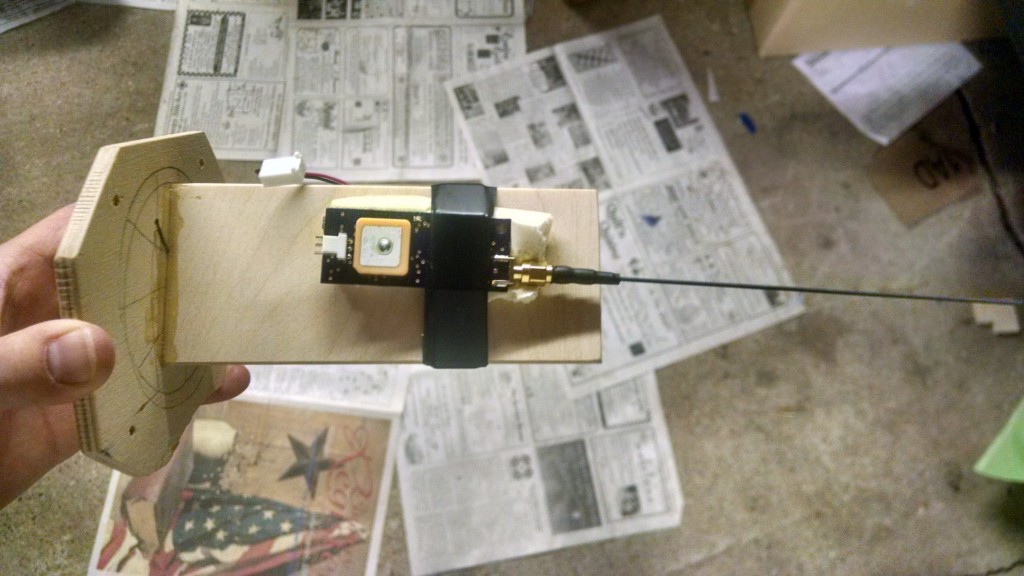

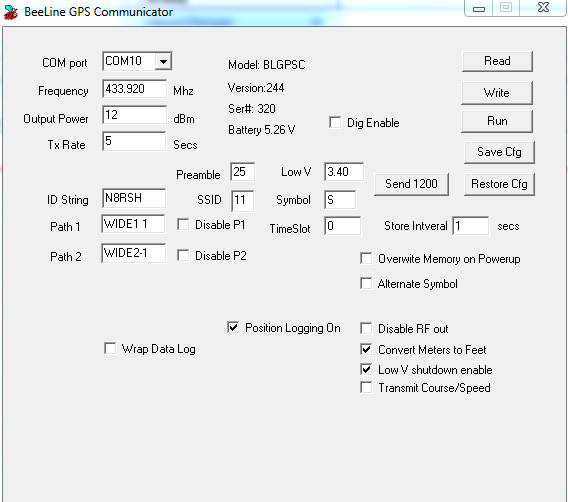

look what came in the mail, my Big Red Bee 70cm GPS APRS unit 🙂 🙂 🙂 Jan 27, 2016

put some 5-min epoxy on the front ebay bulk head on the MAIN side, covering up the sharp parts..

James is inspecting the rocket as a short stack, he approves!

Time to clean up all of the foam on the nose cone, Jan 30, 2016

Only an hour and a half to dig out all of the extra foam.. .. ..

dry fit, looks good

added bolts to the centering ring to be able to hold the tracker cover down.

5-min epoxy on the top of the bolts to keep then from moving around.

Ready for rock poxy, and a centering ring.

Lots of rockpoxy, mmmmm what a mess I can make.

Ring installed, epoxy cleaned up.. let it set now..

Work on the tracker bay, this is a look at the inside, bolt is for support and a handle on the other side.

little 5-min to put it all together

Added more 5-min in to fill in the gap around the bolt

Here is what it looks like.. got to find an other wing nut

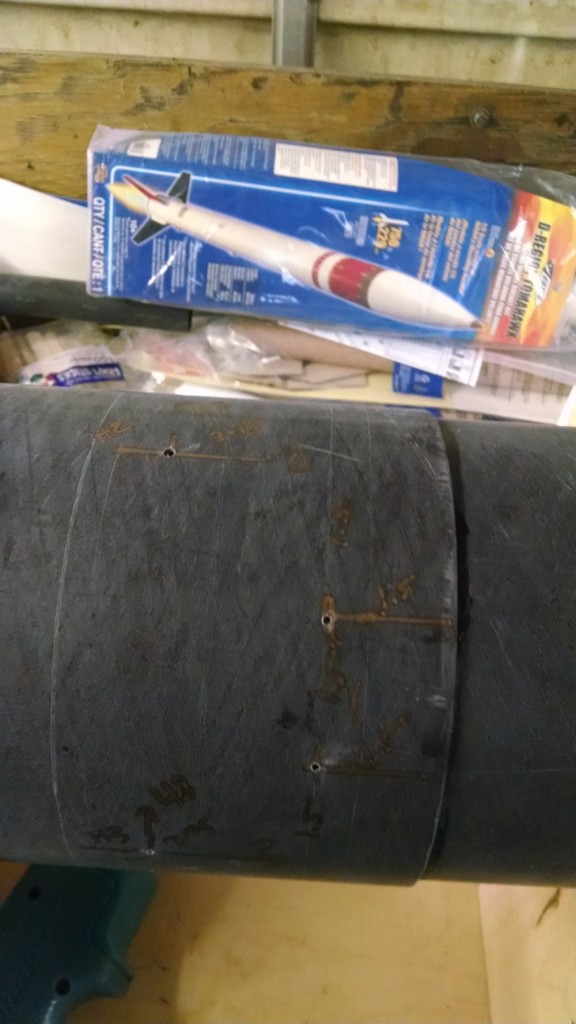

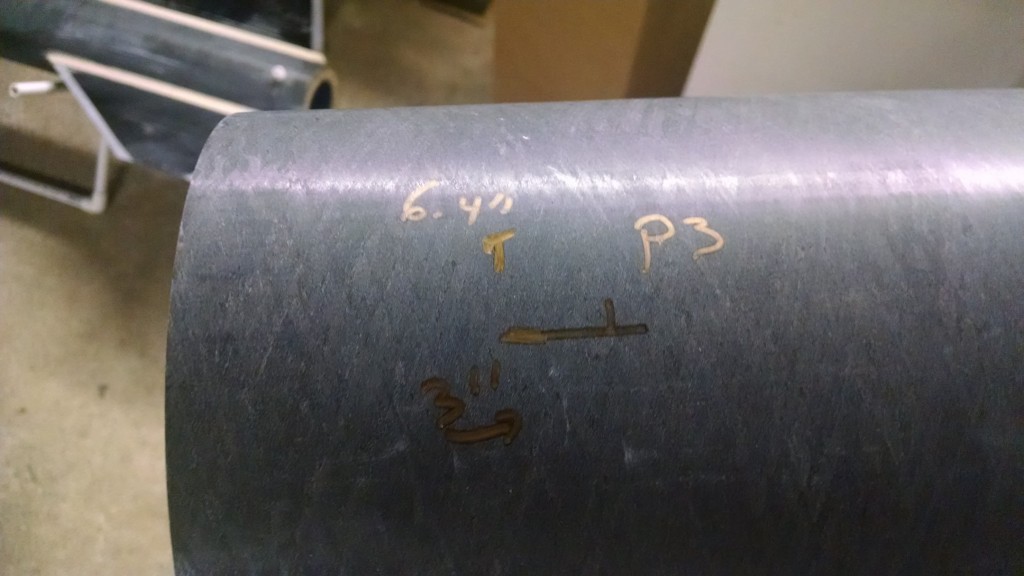

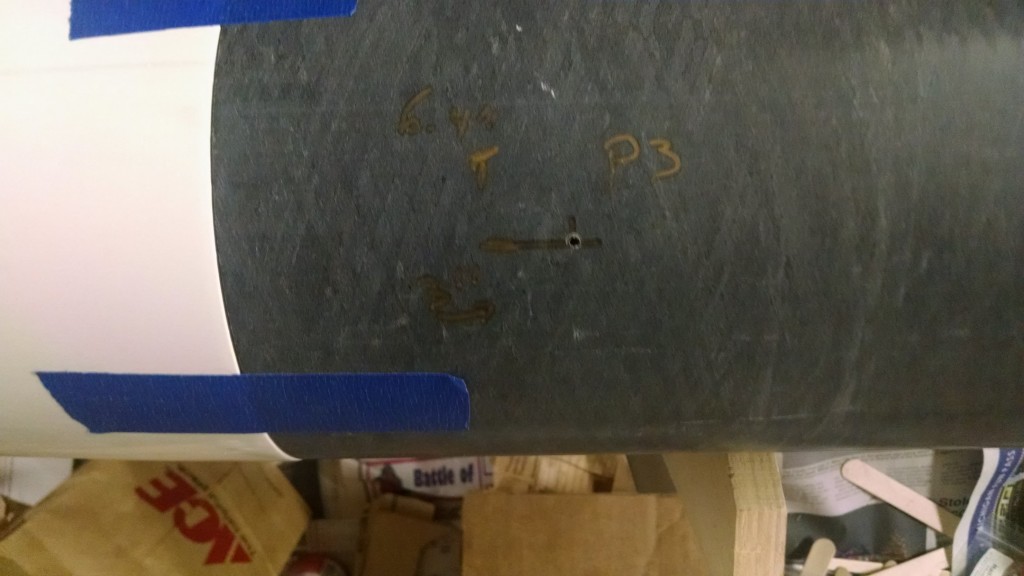

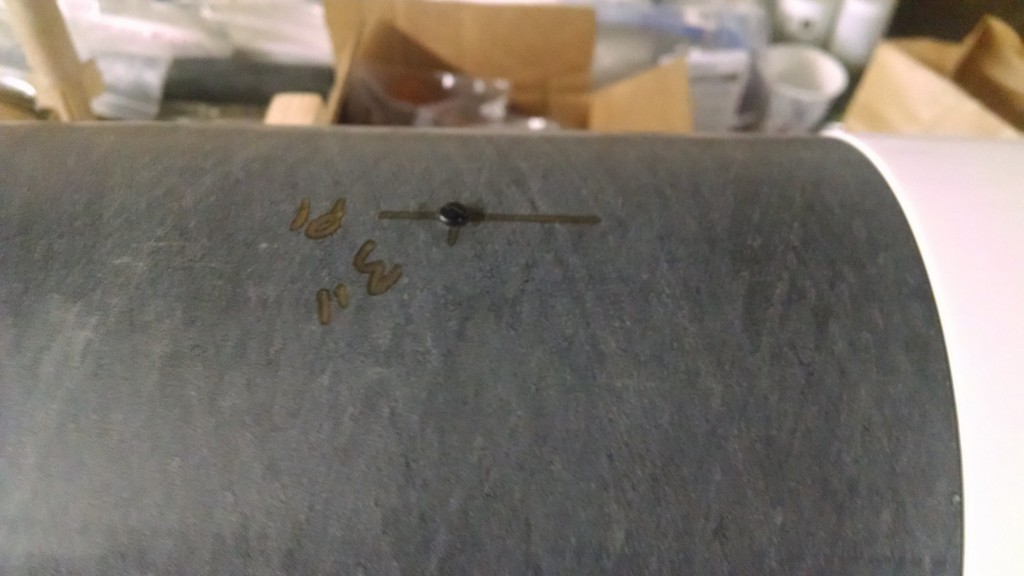

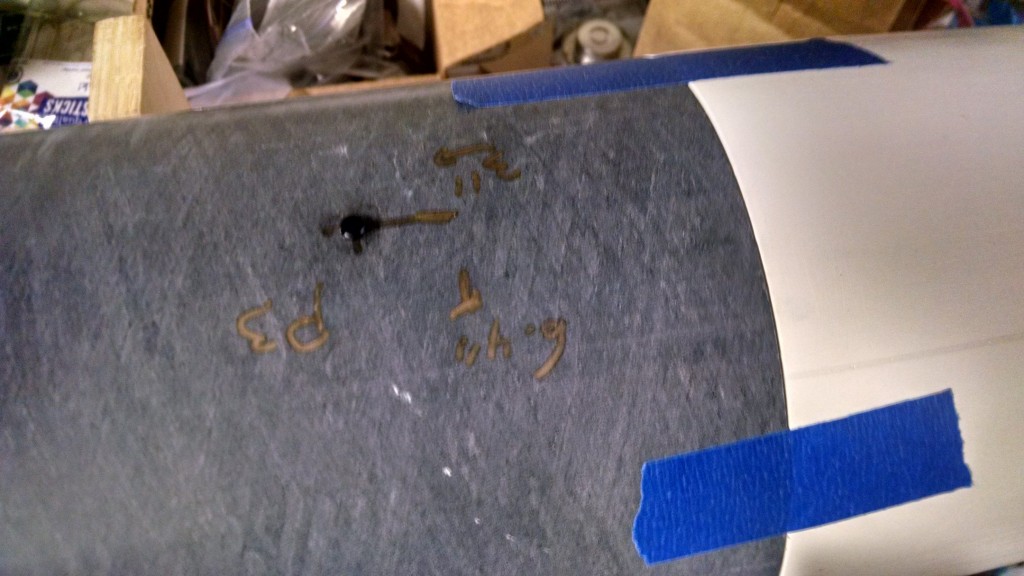

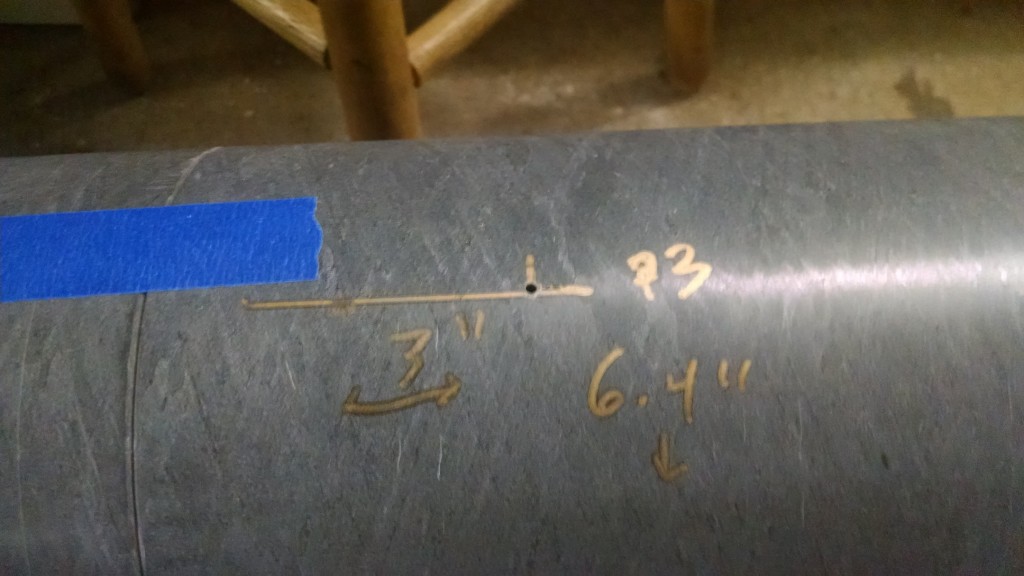

Time to start tapping in shear pin holes.. 3 holes around, 3inches down, 6.4in around from each other 19.25in diameter / 3 = 6.4inches.

nose cone fitted on, with three pieces of tap to hold it in place

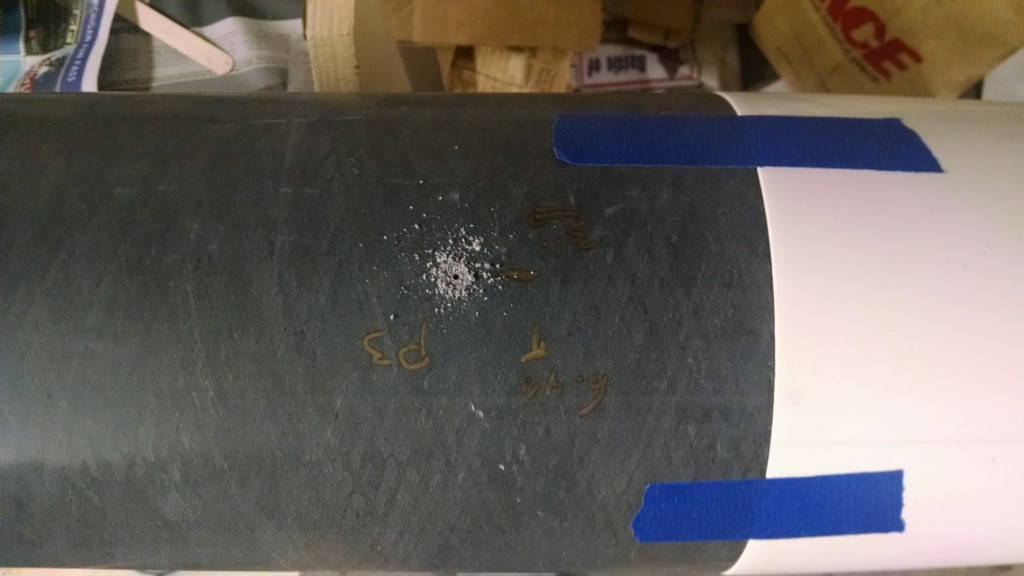

Used a punch to get the hole started, keeps the drill bit from jumping around

looking good, how to get shear pins on the ebay to the booster tube

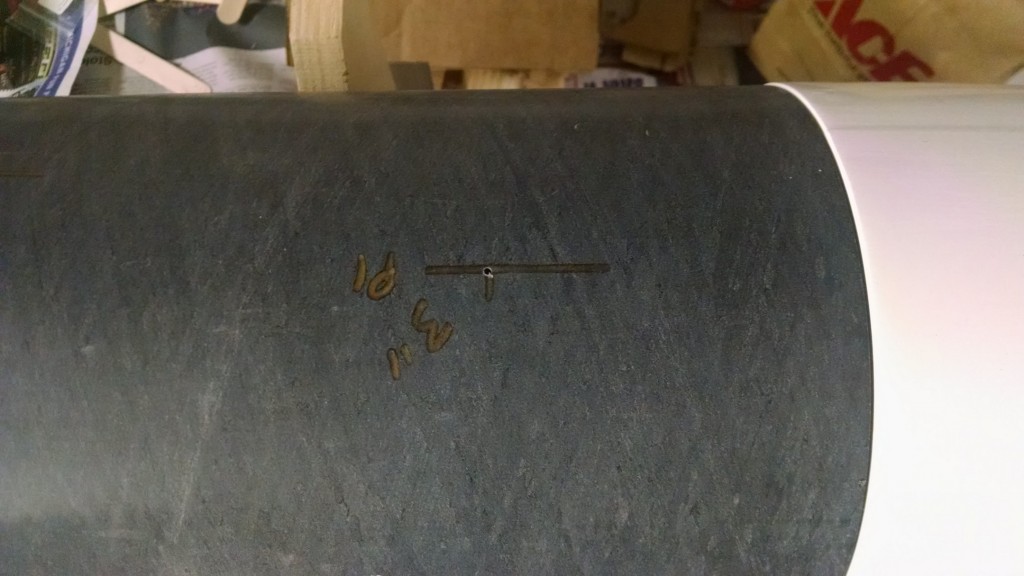

Same math as the nose cone, 3 in down, 6.4in around, tape to hole the tubes while drilling

a punch to help keep the drill bit from jumping around

tap hole

it fits

Ready for deployment testing. But first we need to arm it and load it.

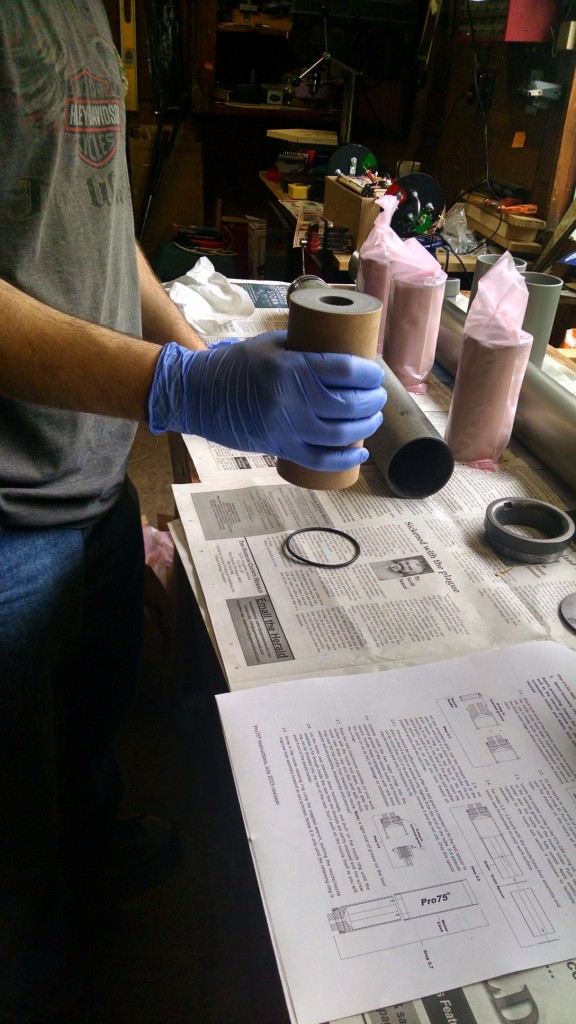

going to use my CTI Pro75 3G case

Covering the forward end of the case to create the correct volume size.

Need to cut the 1in shock cord in half.. 100ft total, 50ft for each deployment side.

from paint can to paint can is 10ft, with 5 passes around equals 50 feet.

And cut it.

I used some painters masking tape to hold it all together so I could cut it.

Time to tie the shock cord to 5/16 quick links. I do the fishing hook knot.

three loops around then back threw the bottom hole.

then dress it up

then I use the painters tape to keep the tail of the knot from flapping, and to protect the cord from the ejection charges.

Here is everything laid out, need to tie loops in for the chutes. 1/3 of the way from the nose cone on the main, and 1/3 of the way from the ebay on the drogue. 1/3 of 50ft is 16 feet.

make a loop and pull it threw.

ready for a chute and protector.

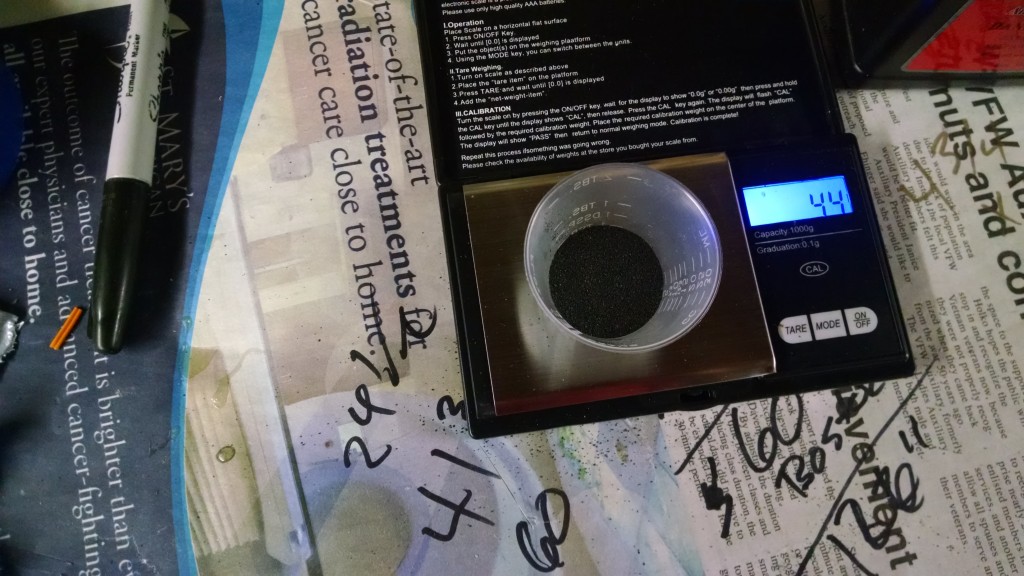

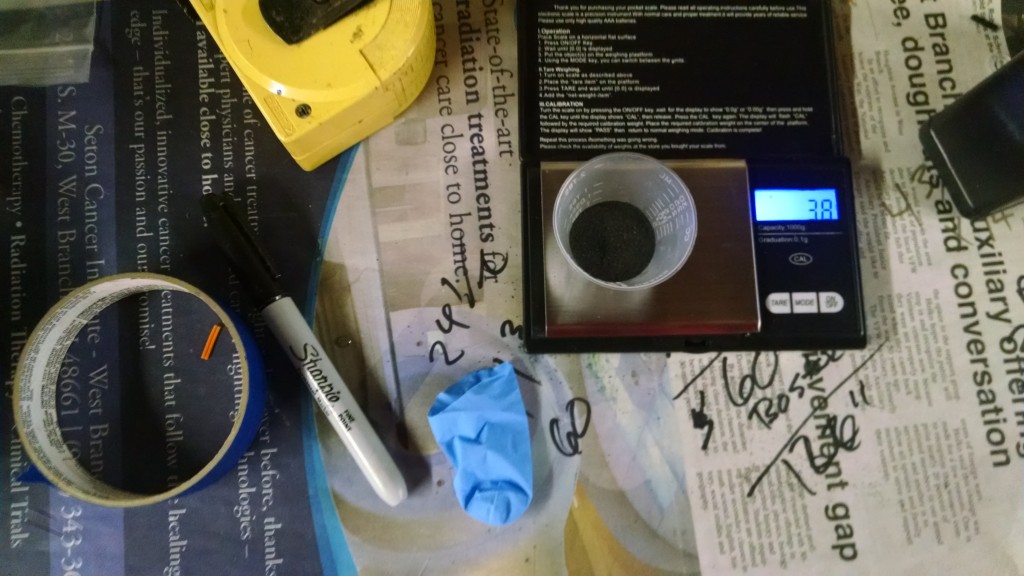

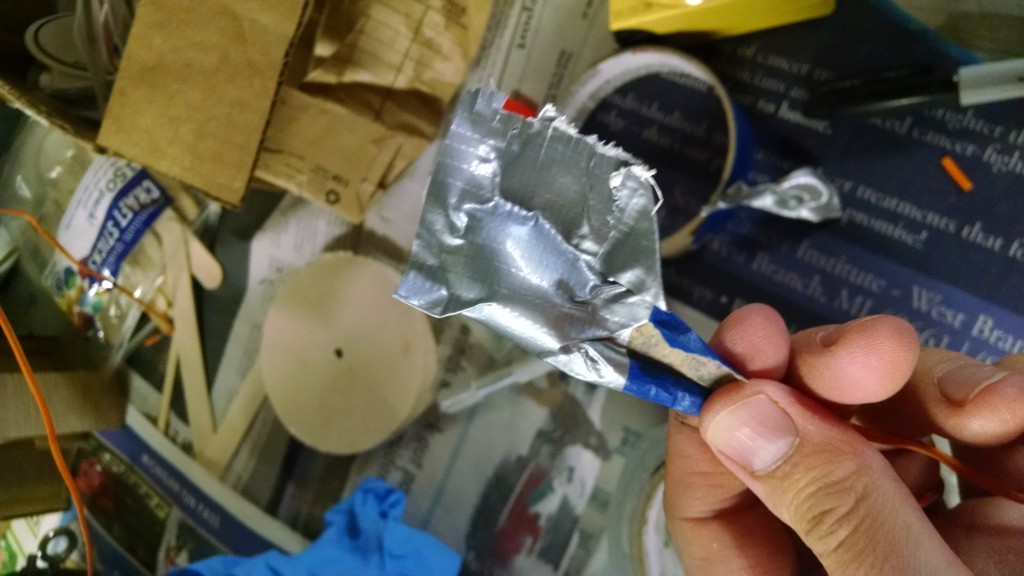

3.8g of BP for the drogue test #1, goes in the glove tip, then duck tape.

tape to hold the bp in the glove tip.

Duck tape to hold and protect the glove tip.

Pulled the wire threw the hole and out the side of the ebay for testing. taped up the terminals for protection during the testing.

Dog puck to protect the chute

pack the chute and the shock cord in the protector

Add three shear pins to the top and the top is ready.

ebay to booster tube … getting the drouge chute and the shock cord in the protector, then load that with dog parf. then add the shear pins to it.

got 12ft on the drogue test #1

Drogue Test #1 2016 02 06 – 3.4g of 4F BP, temp was 32*

Main Test #3 2016 02 06 – 4.5g of 4F BP, temp was 32*

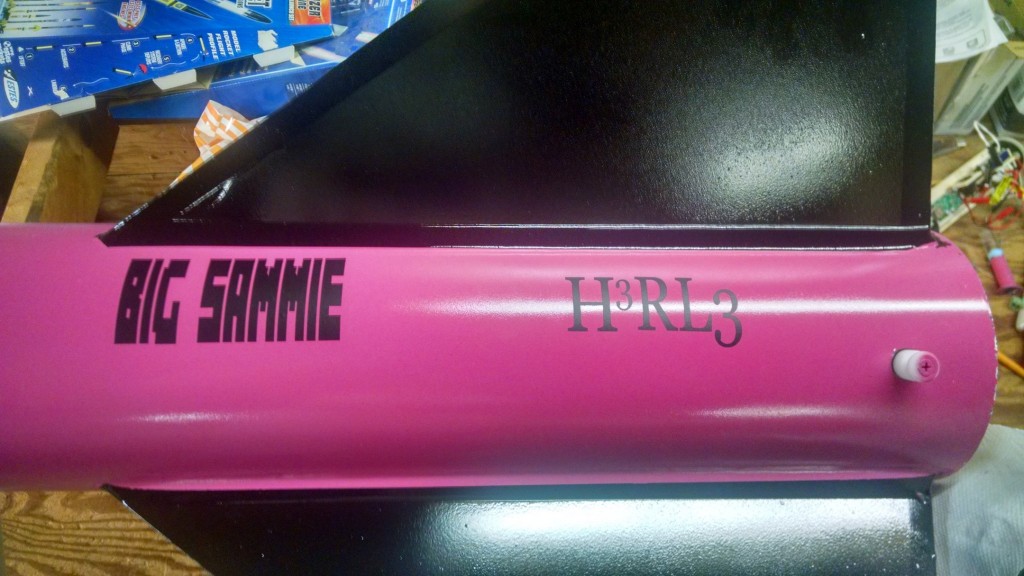

and Sammie wins the color chose of the rocket. Berry Pink with black

Construction and recovery for the Rocket have been approved. 2-20-16

Time for primer !!!! Feb 20, 2016

Time to let it dry, then it will be pink and black

and down goes the pink…. Feb 28, 2016

PINK Let it dry for a week…

Blank fins and two strips… March 5, 2016

March 8, 2016 .. paw stickers added..

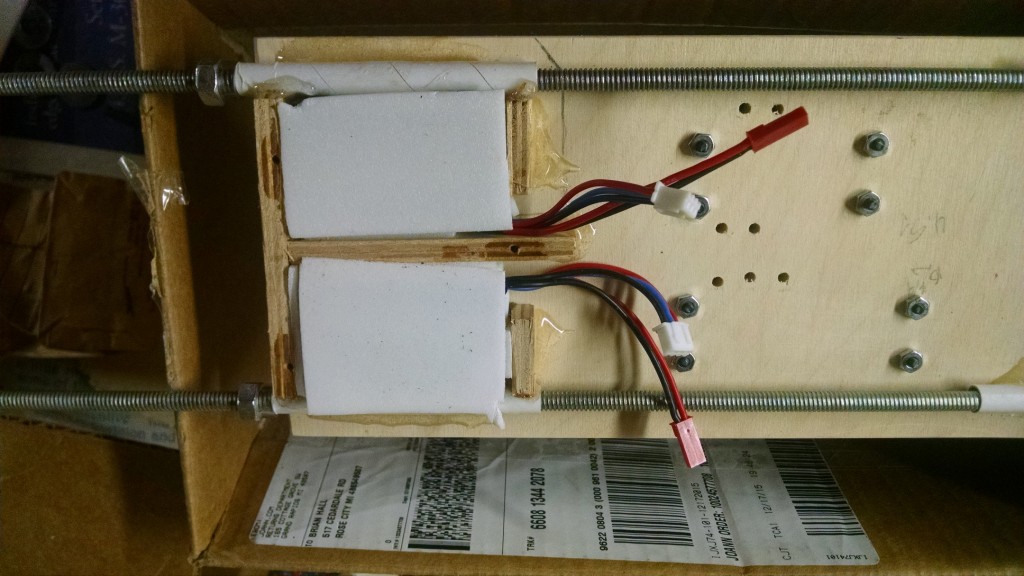

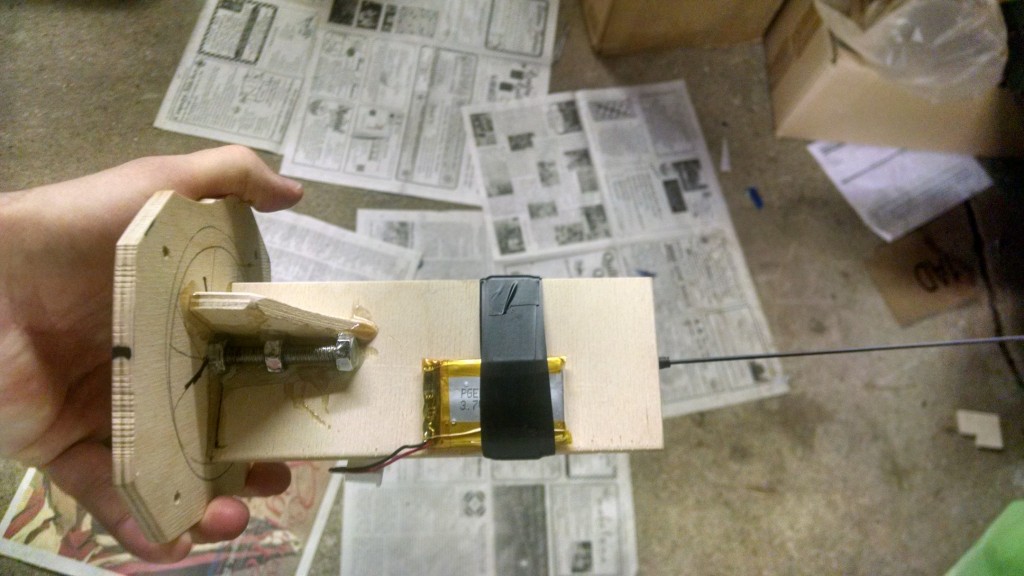

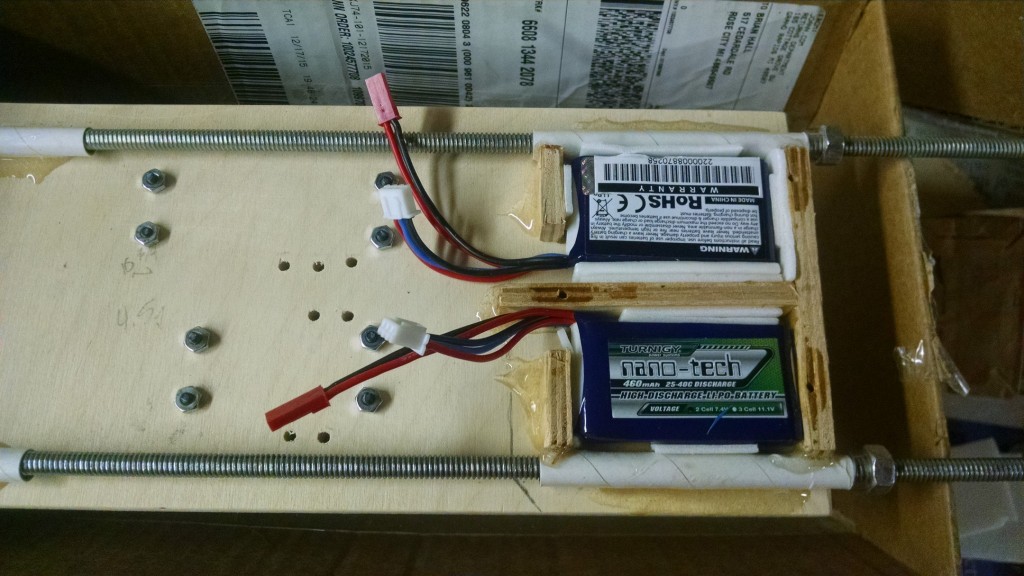

March 8, 2016 starting on the battery bay on the sled..

March 9, 2016 Bottom cover for battery bay

LiPo Batteries in with a little foam to keep it from moving

A bit more foam

bottom view with all of the wires routed

Top view… Green side is Primary and Red side is backup.. the electrical tape to a double protection to keeping the batteries in.

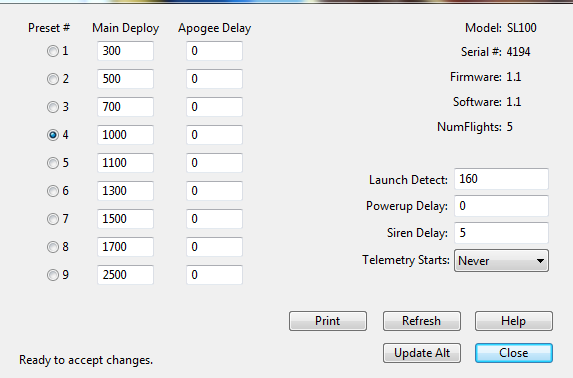

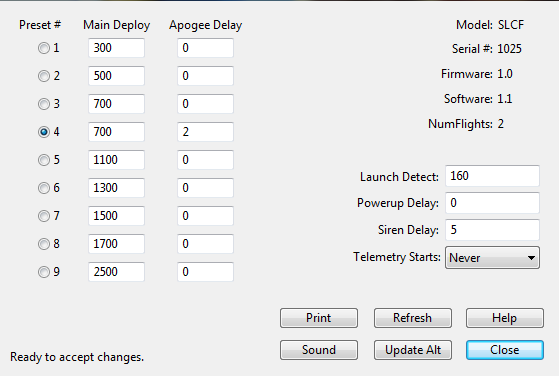

March 10, 2016 Added a Big Red Bee 70cm beacon to the bottom of the ebay.

Mounted Big Red Bee 70cm APRS GPS unit to the tracker sled for the nose cone.

March 12, 2016 Big Red Bee 70cm GPS is programmed.

March 13, 2016 Motor assembly time …

Forward closer with smoke charge inserted.. lubed on the inside of the closer

Rear retaining ring on the nozzle.. two O rings here, inside and outside of the metal ring

front the top.. grain in then o ring, then grain then o ring then grain then o ring then grain then o ring.

sorry is miss the photo of the forward closer and two spacers that go in the top..

Add the AreoPack adapter system from 75mm to 98mm

and I think we are ready to FLY!!!

March 19-20, 2016 Cert Weekend

March 19-20, 2016 Cert Weekend

Published @ January 21, 2015 9:09 pm

Rob’s BP Burrito

Rob’s BP Burrito